Calculating formwork for a beam involves understanding the structural requirements and using precise measurements. A simple way to calculate formwork for beam is to multiply the linear meter (m) of the beam by the formwork width (m).

However, there are several important considerations before performing this calculation. This guide explains the steps in detail to ensure accurate results.

Why Accurate Formwork Calculation Matters

Formwork serves as the temporary structure that supports concrete until it achieves the necessary strength to support itself. Inaccurate formwork calculations can lead to unnecessary material expenses, compromised structural stability, and increased construction costs. By getting it right, you ensure the safety and efficacy of your construction project, while optimizing resources and reducing waste.

Steps to Calculate Formwork for a Beam

Understand the Structural Drawings

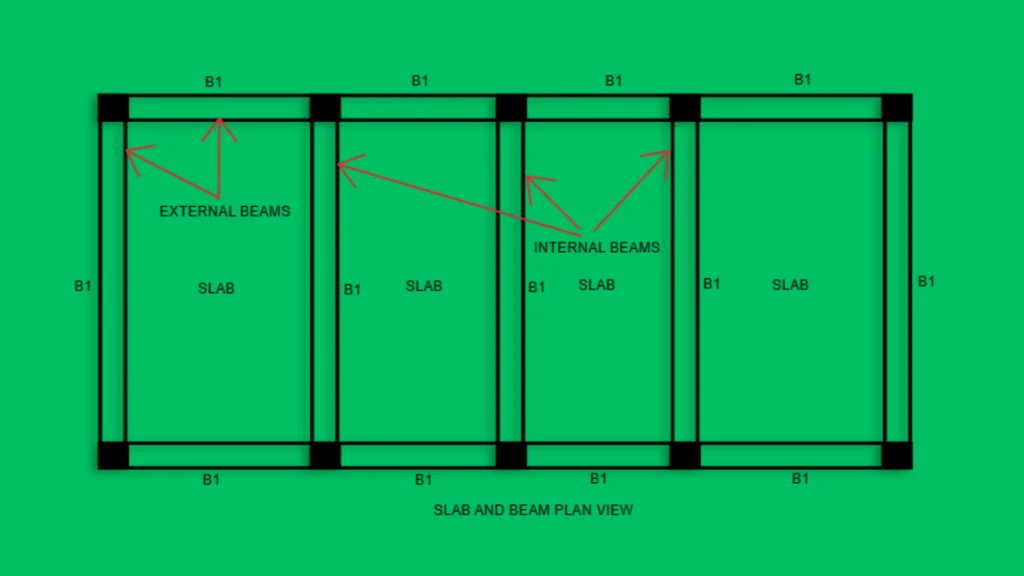

Your first step in calculating formwork is to familiarize yourself with the structural drawings, often available in PDF or CAD formats. These documents are your blueprint for understanding the layout and dimensions of beams within the structure.

- Analyze the Structure: Pay attention to the layout, noting level differences, slab positions, and beam arrangements. This will help you visualize how everything fits together.

- Mark the Beams: Differentiate between internal and external beams by noting them directly on the drawings. This distinction will guide your formwork calculations.

- Measure Beam Lengths: If specific dimensions aren’t provided, use tools like AutoCAD’s dimension tool to measure beam lengths manually.

For example:

- Internal Beams: Total length is 12 linear meters (LM).

- External Beams: Total length is 26 LM.

Separate Internal and External Beams

Differentiating between internal and external beams is crucial due to their differing formwork requirements. Internal beams are surrounded by the structure, while external beams demand additional considerations due to their edge placement.

- Internal Beams: These are located within the structure and interact with other elements like slabs and adjacent beams.

- External Beams: Positioned at the structure’s edges, they require considerations for edge safety and can be susceptible to environmental exposure.

Calculate the Formwork Dimensions

To determine the formwork area, multiply the linear meter of the beam by the formwork height. Let’s break it down with examples:

- Internal Beams: Suppose the beam width is 400 mm and the beam depth is 600 mm. For internal beams, a 1.5-meter formwork is sufficient. Thus, the formwork area is calculated as 12 LM x 1.5 meters = 18 square meters (sqm).

- External Beams: For external beams, consider additional space for a working platform. Suppose the same dimensions apply, but you need a 2.5-meter-long formwork at the periphery. The formwork area becomes 26 LM x 2.5 meters = 65 sqm.

The total formwork area for both internal and external beams in this example is 83 sqm.

Important Considerations

Formwork Material:

- Include the thickness of materials like plywood (e.g., 18 mm thick) in your calculations to ensure the formwork dimensions are accurate.

- Use durable materials to withstand the weight of the wet concrete and the pressure exerted during casting.

Safety Measures:

- For external beams, ensure adequate safety provisions to prevent accidents, especially when working on higher levels or near edges.

Worker Space:

- Always account for sufficient space for workers to install and dismantle the formwork safely and efficiently.

Why Differentiate Between Internal and External Beams?

- Internal Beams: Require allowances for adjoining slabs and other structural elements. The formwork must be designed to accommodate these connections while ensuring stability.

- External Beams: Positioned at the structure’s edge, they may face environmental exposure and require sturdy formwork to maintain integrity during construction.

Final Thoughts

Calculating formwork for beams is a crucial process that involves meticulous analysis of structural drawings and precise measurements. By distinguishing between internal and external beams, considering material allowances, and prioritizing safety, you can accurately estimate the required formwork area.

This method not only saves time and costs but also ensures a seamless construction workflow. Double-check your calculations and collaborate with engineers to address any project-specific challenges. With these insights, you’re equipped to master formwork calculations and contribute to the success of your construction projects.